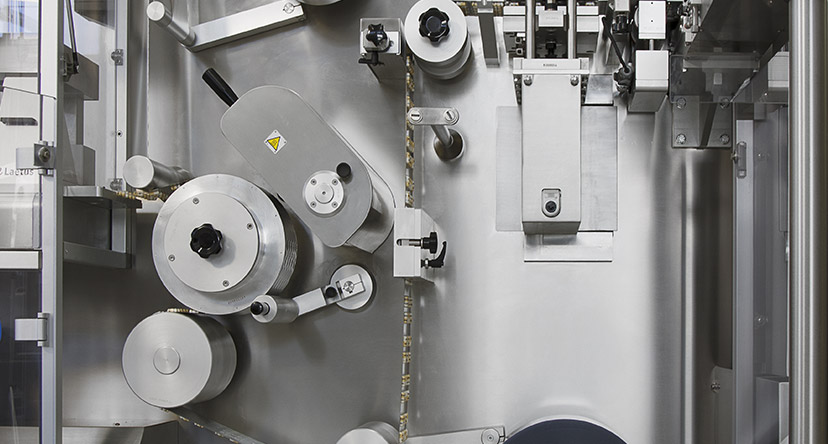

Automatic blister machine, particularly suitable for frequent size changeovers, small and medium outputs, and production on a fee or contract basis.

Ultra-compact and easy to fit in small spaces, the TF120 was designed in accordance with GMP standards, with a stainless steel balcony construction and technologically advanced features, despite its small size.

Learn more

The 5 servomotors for the following stations:

• Forming

• First and second film dragging roller

• Sealing

• Numbering

• Blister cutting

make size changeover quick, easy and precise, as all the parameters saved in the panel are set up automatically, without the need to make any manual adjustments.

Operating interface with an intuitive industrial PC that can be managed via remote connection for online technical support.

Blister outfeed belt in line or at 90° for automatic connection to the cartoning machine.

ASSETS

• Compact layout

• Ideal for frequent size changeover

• Remote support capability

ADDITIONAL MAIN UNITS AVAILABLE:

• Vibrating pre-feeding hopper

• Dedicated or universal automatic feeding, depending on the type of product to be packaged

• Camera for blister pack conformity inspection

• Printing of coding/batch number with stamps, ink-jets or other systems

• Automatic ejection of non-conforming blister packs

Close