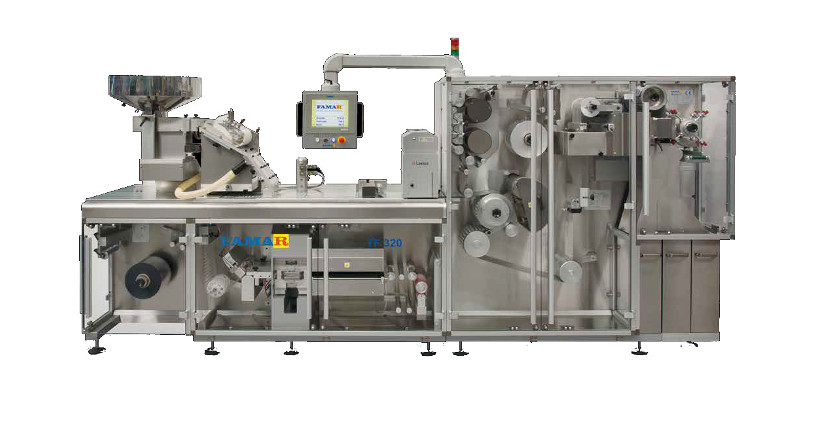

Automatic blister machines suitable for medium-high outputs, with a balcony construction to allow for complete separation of the strictly pharmaceutical zone from machine control components; designed in accordance with GMP standards.

All five main motorised units are controlled by servomotors:

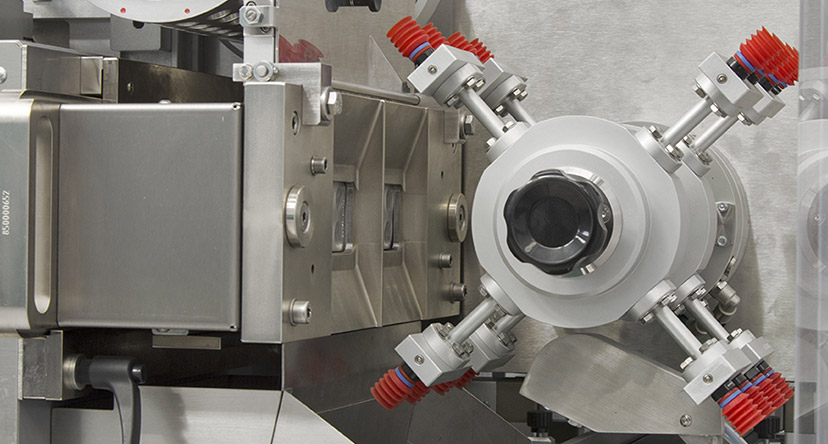

Forming unit

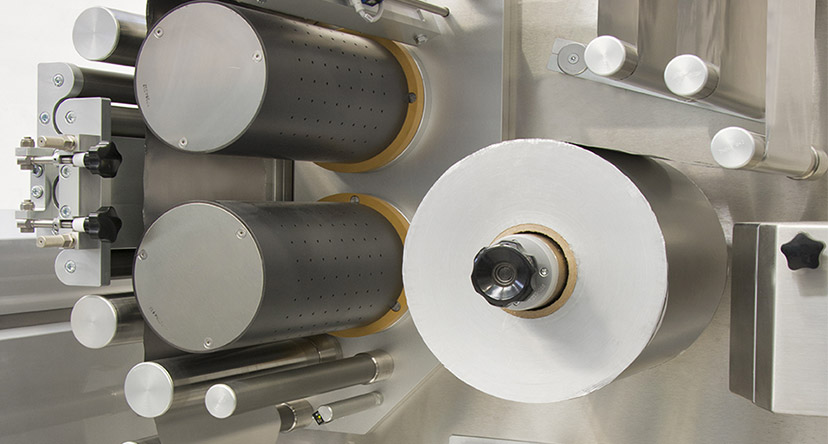

Thermoforming film dragging unit

Roller sealing unit

Film dragging unit up to the cutting zone

Blister coding and cutting unit

Learn more

The TF320 can work 1, 2, or 3 rows of blister packs, ensuring high production efficiency with minimum material waste.

Size changeover, which is facilitated by servomotors, does not require adjustments related to the forming pitch and blister pack width; the feeding zone has been specially designed to improve hygiene and reduce cross-contamination.

Operating interface with an intuitive ASEM industrial PC that can be managed via remote connection for online technical support.

Complete accident-prevention protection with access controlled by micro safety switches.

Blister outfeed belt in line or at 90° (front or back) for automatic connection to the continuous or alternate motion cartoning machine.

ASSETS

• Suitable for packaging of a wide range of products

• Versatile: can connect to cartoning machines

• Remote assistance capability

ADDITIONAL MAIN UNITS AVAILABLE:

• Vibrating pre-feeding hopper

• Dedicated or universal automatic feeding, depending on the type of product to be packaged

• Camera for blister pack conformity inspection

• Checking for micro holes in forming aluminium

• Printing of coding/batch number with stamps, ink-jets or other systems

• Online printing of covering material

• Cross punching of blister packs

• Automatic ejection of non-conforming blister packs

Close