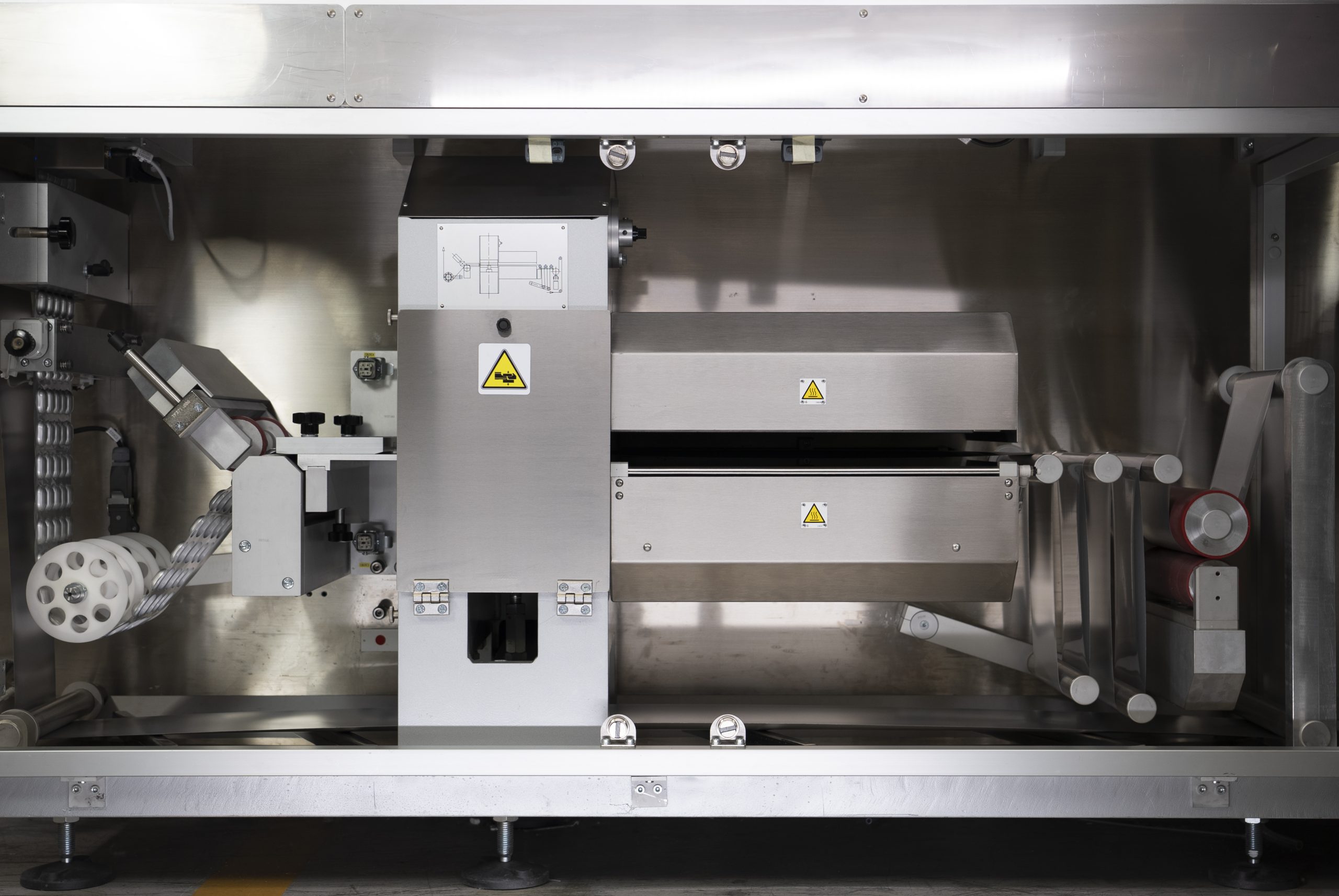

Automatic blister machines suitable for medium-high outputs, with a balcony construction, designed in accordance with GMP standards.

The main working stations are controlled by servomotors:

Forming unit

Thermoforming film dragging units

Roller sealing unit

Blister coding and cutting unit

Learn more

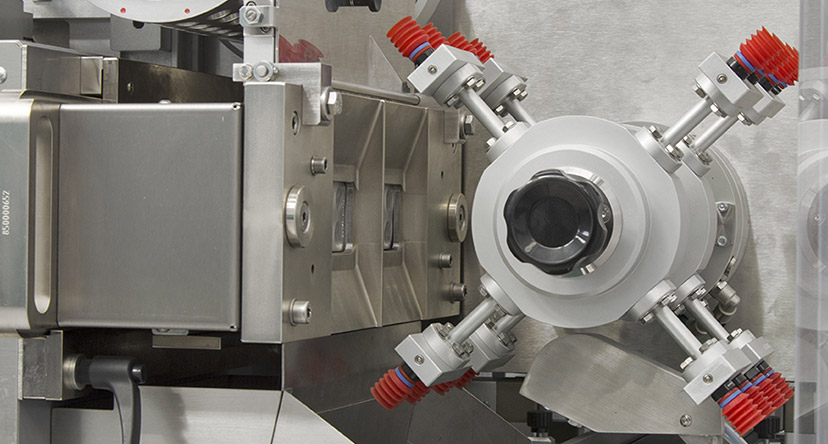

The three-lane TF320 ensures high flexibility and production efficiency with less material waste.

The servo-driven working stations allow an easy and quick size changeover.

Operating interface with an intuitive industrial PC that can be managed via remote connection for online technical support.

Blister outfeed belt in line or at 90° (front or back) for automatic connection to the continuous or alternate motion cartoning machine.

HIGHLIGHTS

• High performance and flexibility perfectly combined

• Versatility in connection with cartoning machines

• Remote assistance capability

ADDITIONAL MAIN UNITS AVAILABLE:

• Vibrating pre-feeding hopper

• Dedicated or universal automatic feeding, depending on the type of product to be packaged

• Camera for blister pack conformity inspection

• Checking for micro holes in forming aluminium

• Printing of coding/batch number with stamps, ink-jets or other systems

• Online printing of covering material

• Cross punching of blister packs

• Automatic ejection of non-conforming blister packs

Close