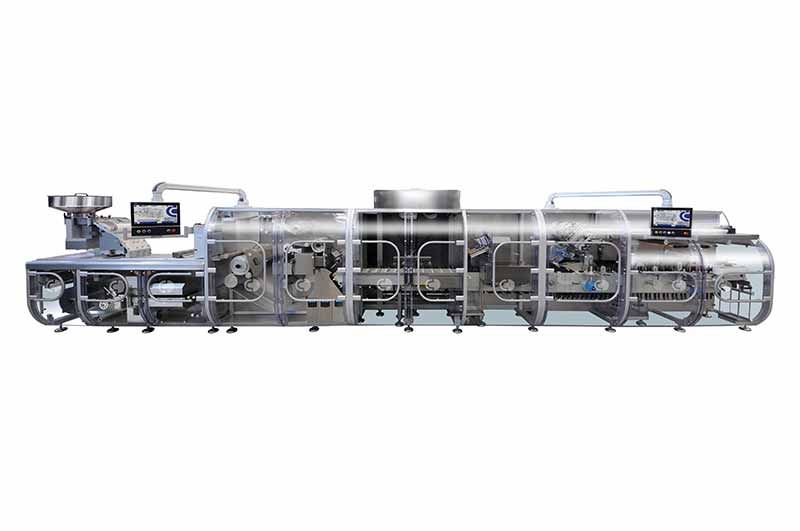

High efficiency in terms of production and flexibility, in less than 10 meters length.

Composed by:

- Roller sealing blister module;

- Positive blister transfer unit;

- Continuous motion cartoning module

Learn more

Completely servo driven, the blister section can work on 1, 2 or 3 lanes in order to ensure high production efficiency with minimum material waste.

Size change-over does not require adjustments related to the forming pitch and blister pack width; the feeding zone has been specially designed to improve cleaning and reduce cross-contamination.

The cartoning section is equipped with innovative quick release systems and digital position indicators that allow a simple and fast size change-over.

Operating interface with an intuitive ASEM industrial PC that can be managed via remote connection for online technical support.

ASSETS

– Compact layout

– Blister positive transfer

– Size change-over with digital position indicators

– Electricity and compressed air low consumption

Close